Thank you for your comprehensive advice. Still a lot to learn😀.

NicoClock

8

Posts

2

Topics

A member registered Oct 30, 2024

Recent community posts

PixelCNC Has Moved: deftware.org community · Replied to Deftware in Time loss due to (unnecessary?) safe positioning during carving

PixelCNC Has Moved: deftware.org community · Created a new topic Time loss due to (unnecessary?) safe positioning during carving

It is great fun to work with PixelCNC. I am currently working on a photo conversion to 3D. That works well but I have a question. In the simulation of PixelCNC I see that the bit neatly finishes the canvas row by row without interruptions during 3D parallel carving. I use the G-code in Candle and there I see that the bit is very often brought to the safe height and then continues. That takes a lot of time. Why this difference between the simulation and the execution (in Candle) and can this be prevented. I hope I explained it well. I can of course add the G-code if desired. Best regards, Nico

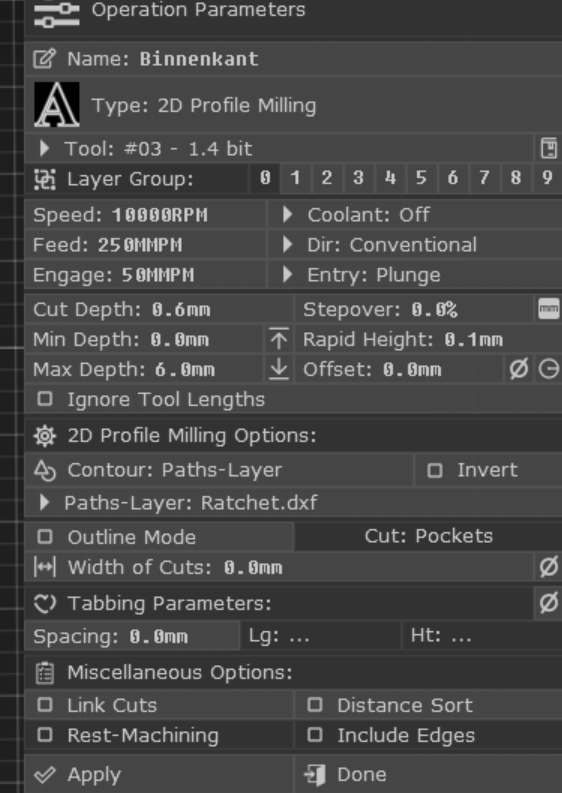

As a relative CNC beginner, I have the following question. I have created my first G-code in PixelCNC, but my machine starts above the material instead of in the material. I compared the G-code start with my current CAM (Easel) and see the following difference (it is not he same project). Easel starts at Z6.000 and goes to Z-0.600. PixelCNC starts at Z6.100 and goes to Z5.40. Please help. PixelCNC: ( Generated by: PixelCNC v1.84b ) ( Post: GRBL Metric.txt v1.10 ) G21 G90 G91.1 ( Buitenkant 1.4 bit ) ( Spindle: CW 10000 ) M3 S10000 G0 Z6.10 X15.42 Y22.07 G1 Z5.40 F50 X15.26 Y22.20 F250 X15.13 Y22.37 Y22.61 Easel: G21 M3 S10000 G90 G1 Z6.000 F228.6 G0 X59.413 Y149.523 G1 Z-0.600 F75.0 G1 X59.504 Y149.653 F350.0 G1 X59.475 Y149.802 F350.0 G1 X59.347 Y149.891 F350.0