Hi Pluto,

The project file looks fine, the G-code looks fine. It must be something with your CNC controller. After it reaches the XY coordinate at the end of the cut it should then be rapiding up to Z10, which would be 10mm above the workpiece - assuming that Z0 is the top-surface of the workpiece. If you can manually issue commands to your machine, zero the origin somewhere up in the air and then run a G0Z10, and it should move up 10mm. If it doesn't move 10mm upward from the established machine origin, or moves downward, then the controller probably isn't zeroed out where it's supposed to be for the Z axis.

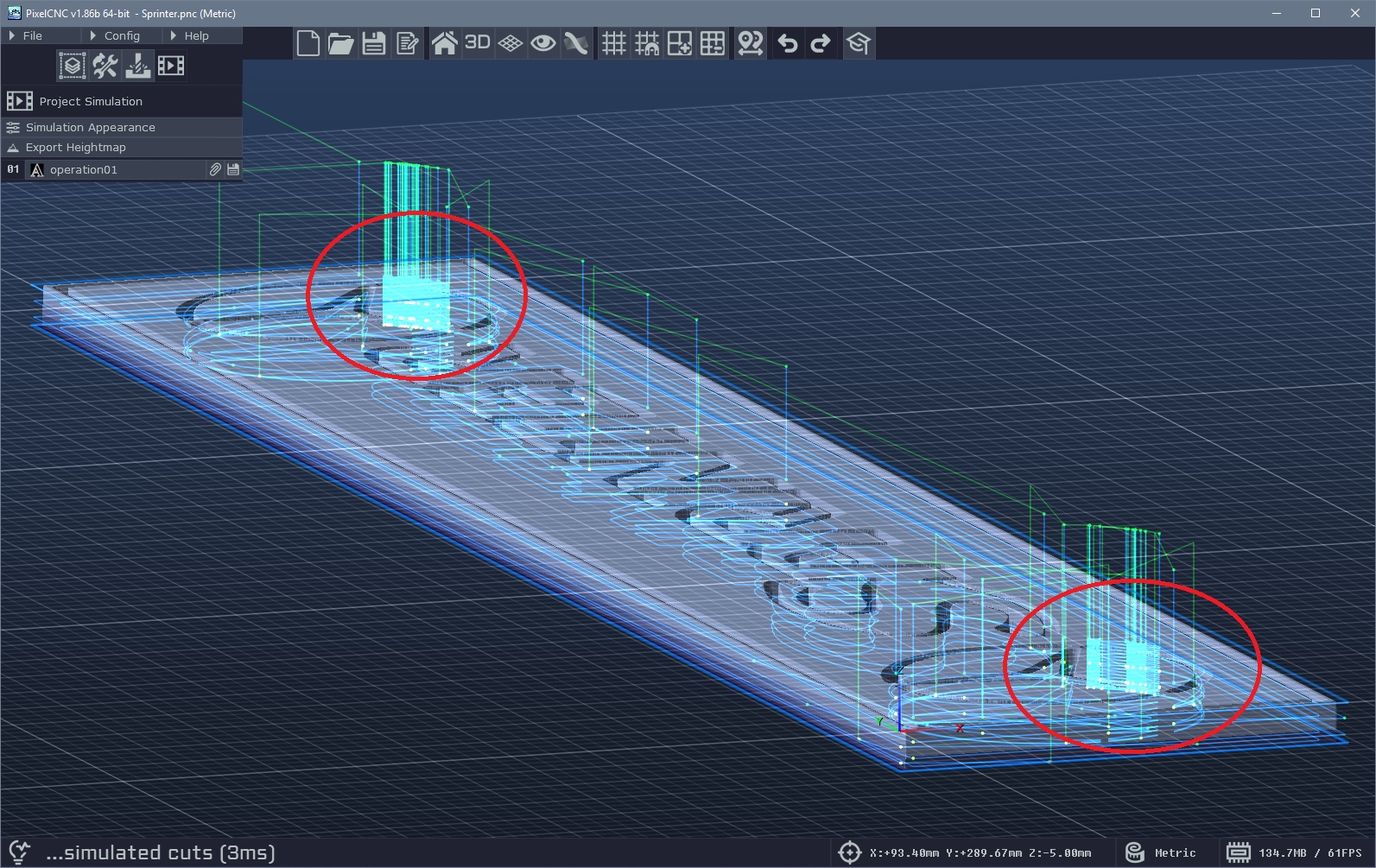

There does appear to be a toolpath artifact that's resulting in many small individual cuts in two spots in your project:

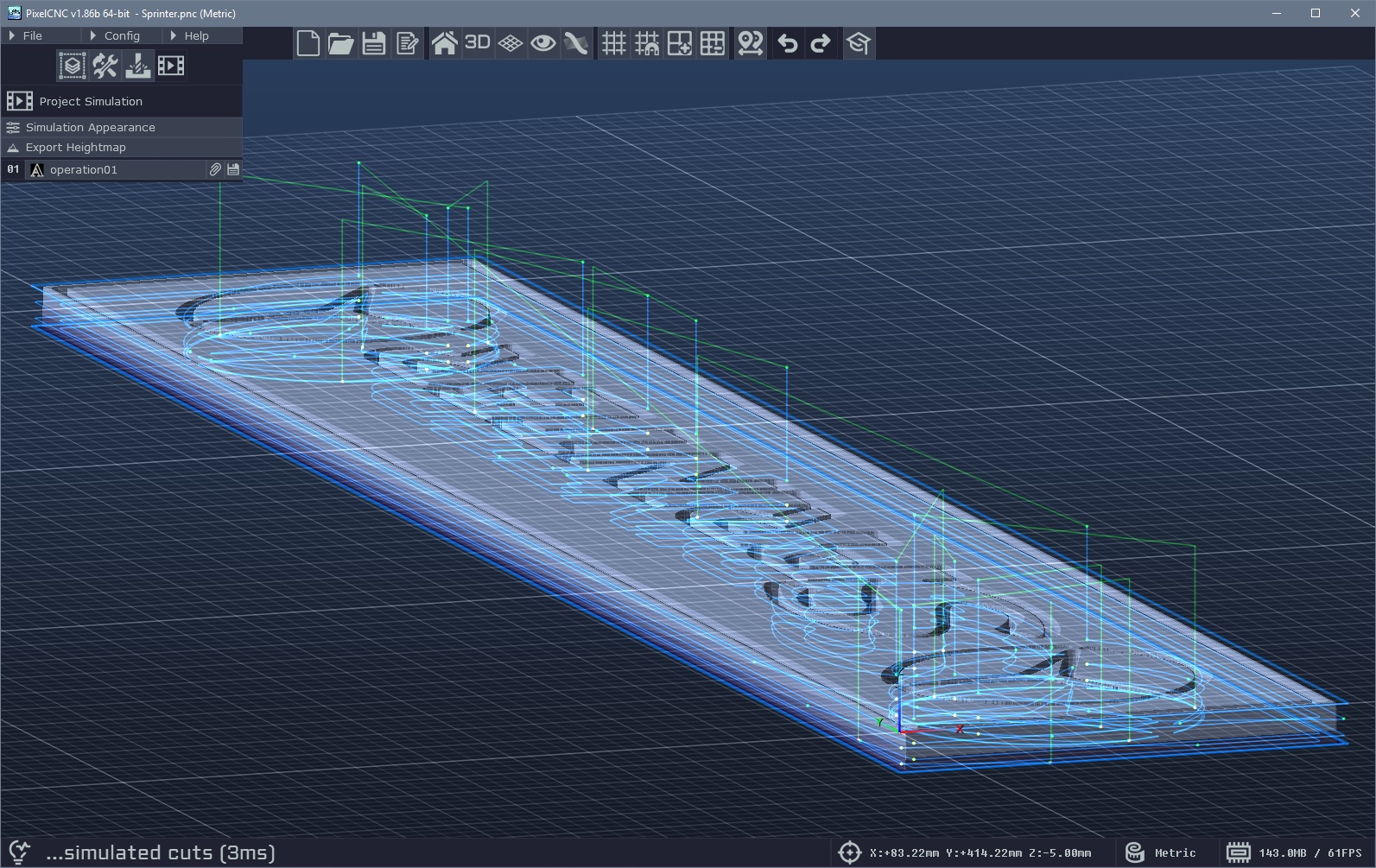

This is caused by a lack of canvas resolution. Increase your Canvas Resolution to 200ppi to get the proper cuts that I imagine you're going for:

Those cutpaths might've been what caused your cutters to break? Let me know what you find.

- Charlie