Hi all,

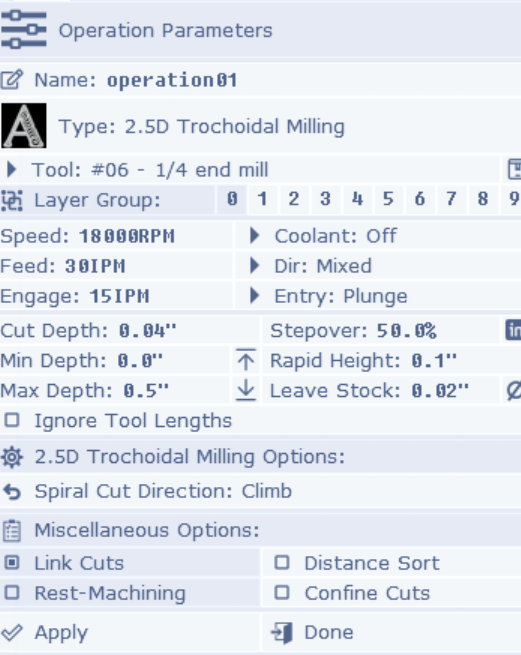

I'm doing a relief carving, roughing, finishing and perimeter passes, I followed the tutorial, everything looks right, the roughing pass carves out, I change the bit, re-zero the Z, and when I start the finishing pass the bit is floating along above the work piece a 10th of an inch or so. I'm sure it is something simple I am missing, but I am stumped. Pics of roughing and finishing settings attached. Any help is appreciated.