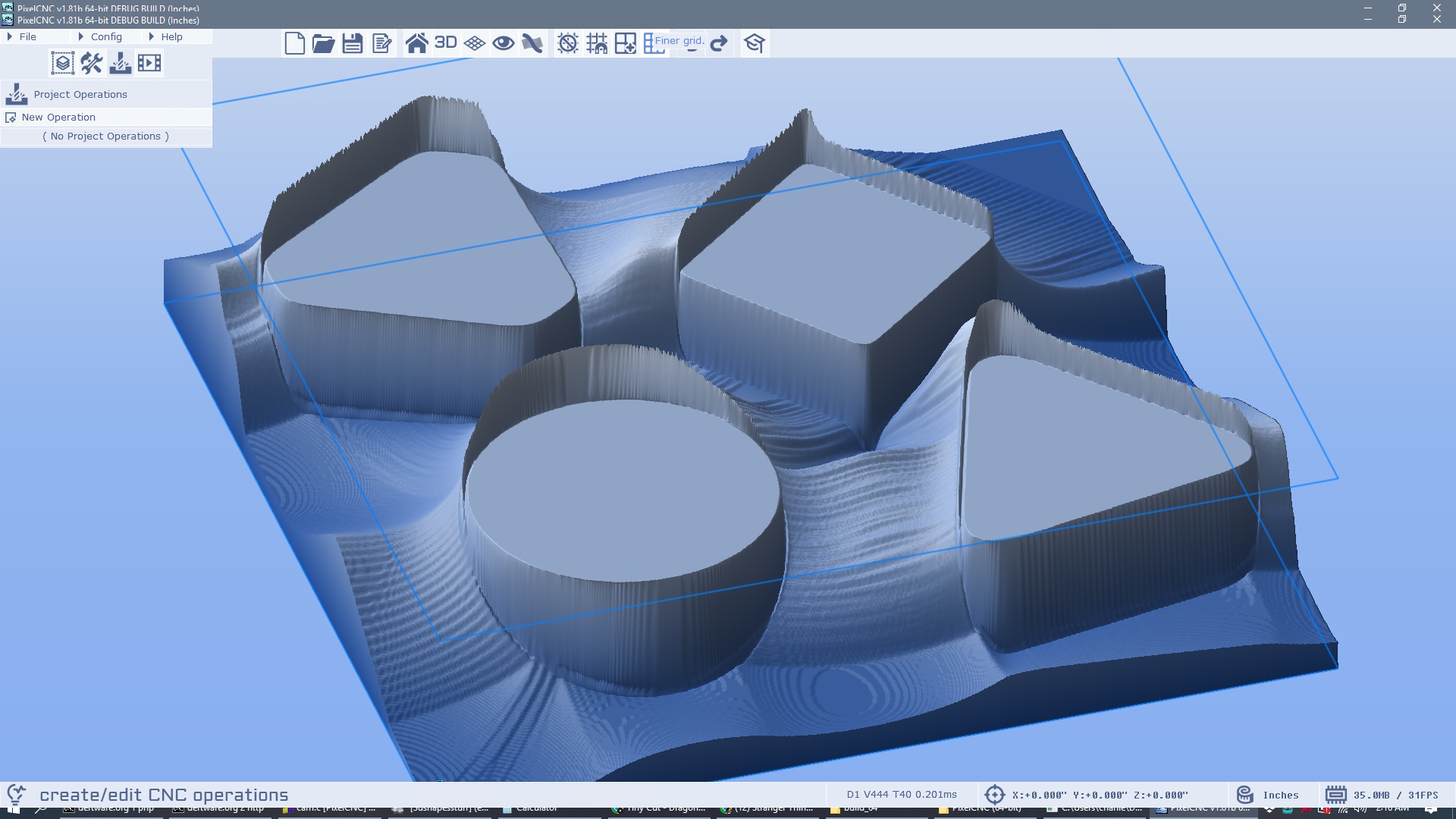

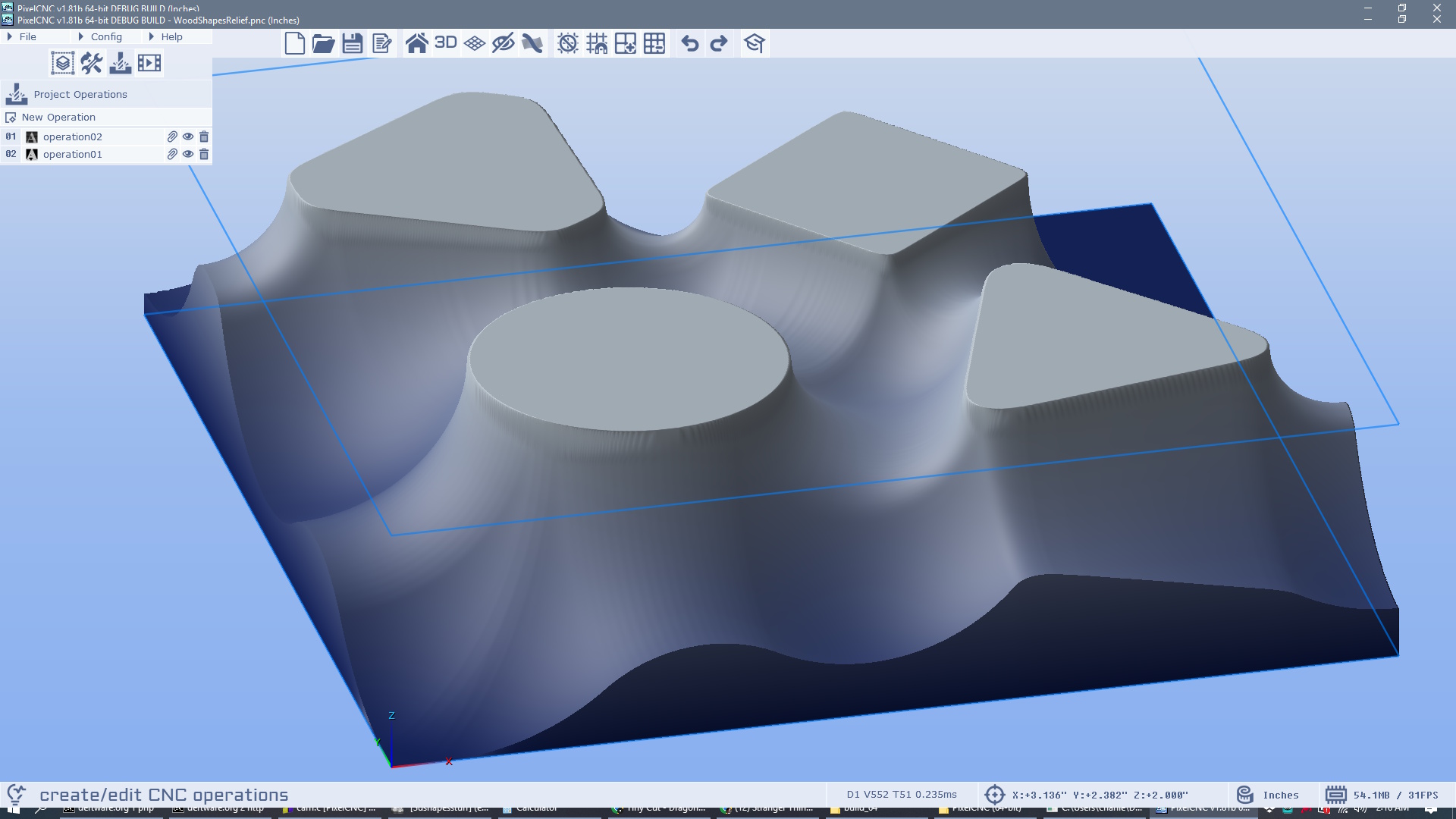

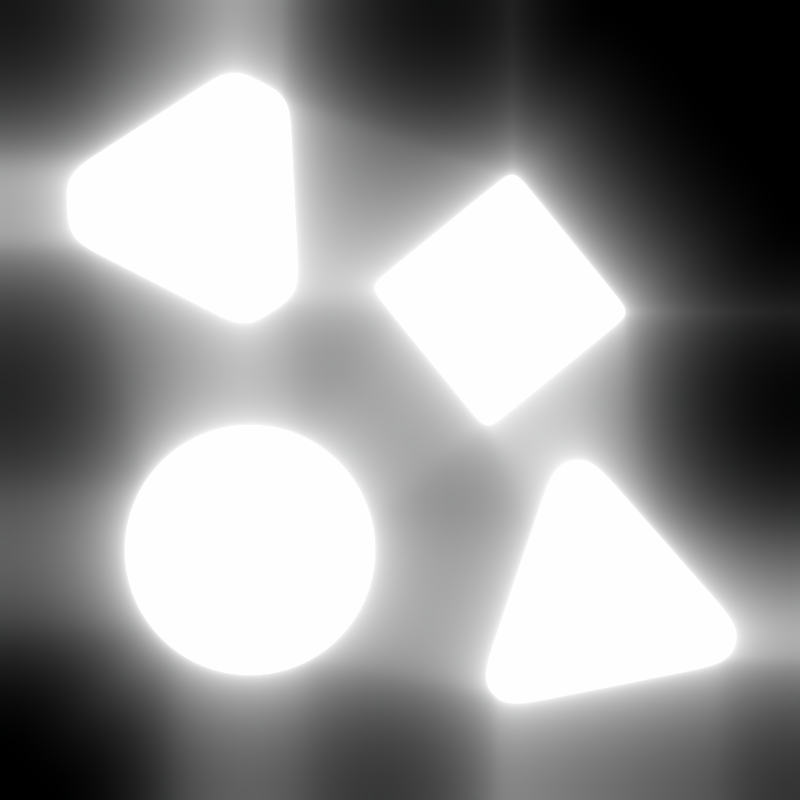

Hi, I am thrilled. As a new user to PixelCNC I tried to see how well a high detailed cut of 20mm would be delivered in fine grain wood. I found a grey scale photo of jewellery in the shape of a dragonfly.

I used a number of bits, a 1/8” flat, a 1mm ball and a 60degree v-bit. It was amazing to see my machine gradually cut this out, especially the attempt to cut out the wing veins. 1/100mm layers was used to finalise it at 1/2mm depth.

What made this extra special to me was that it done on my home made, designed and built machine done withwith a hack saw, file and drill press.

There were some challenges. One significant one was my dismal start where I couldn’t get anywhere near the resolution of showing any wing details at all. The answer, canvas resolution … 1000pixels did it. Of course the quality of the wood is a significant factor.

For this example I used scrap timber hardwood decking. I’ve no idea what it is. It’s medium hardness not anywhere as hard as Australian Eucalyptus hardwood.

My understanding of the cutting parameters is growing, albeit slowly. My earlier cuts were abandoned as taking far too long. 6 hours and still not finished is the worst and depressing. I did get it down to 2.5 hours. Most of this was in cutting the wing details. Surely I can do better.

Another area for me to grow my understanding is cut type. I need more experience to best know what to use where and when. Currently it looks like the spiral 3D is the most efficient. Profile 2.5d is good too for roughing.

The cutting out of the block worked well when I worked out the offsetting to get the border spacing. I did though need to do trial and error to get the supporting tabs in preferred positions. In the example above I did have a border alignment issue. My mistake done when changing the bit. I need to take more care.

Now I know how detailed I can get I will start progressing to bigger carves. I can fit A3 and in the distant future maybe a sheet A3+A3 long. The challenge is there.

Aluminium is another. Maybe I could try this out on 3mm sheet, make it like a pendent?

What are your challenges?